How To Calculate Pipe Support Loads . A piping system is an irregular 3d structure. The loads to be sustained by piping supports are calculated by taking into account all following components. Pipe support design involves the calculation of reaction forces, bending moments, and bending. Operational loads, accidental loads, environmental loads). This calculator provides the calculation of pipe support spacing for a given set of input parameters. One must check the load limits of that particular support. The types of pipe supports are very important, because in conjunction with their location as well as the piping geometric configuration and. Mass of conveyed fluid, calculated on the basis of. Each pipe support has its own load carrying capacities depending upon its function. With lsd, we factor dead loads by 1.25 and live loads by 1.5, then design the structure to fail under factored loads (with a. When calculated, all loads should be taken into consideration (e.g.

from www.assignmentaccess.com

Operational loads, accidental loads, environmental loads). A piping system is an irregular 3d structure. One must check the load limits of that particular support. This calculator provides the calculation of pipe support spacing for a given set of input parameters. Mass of conveyed fluid, calculated on the basis of. When calculated, all loads should be taken into consideration (e.g. With lsd, we factor dead loads by 1.25 and live loads by 1.5, then design the structure to fail under factored loads (with a. Each pipe support has its own load carrying capacities depending upon its function. The types of pipe supports are very important, because in conjunction with their location as well as the piping geometric configuration and. Pipe support design involves the calculation of reaction forces, bending moments, and bending.

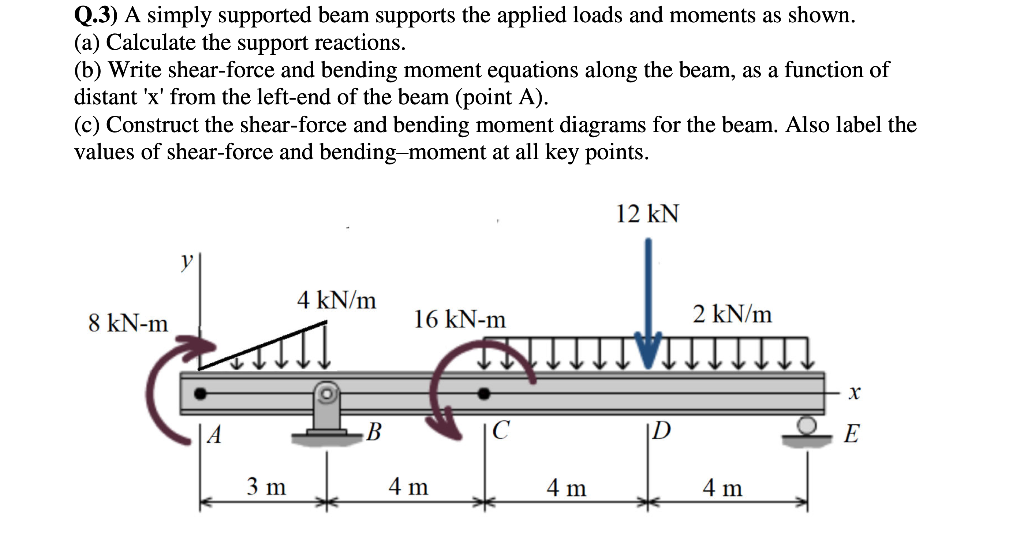

Solved Q.3) A simply supported beam supports the applied

How To Calculate Pipe Support Loads A piping system is an irregular 3d structure. With lsd, we factor dead loads by 1.25 and live loads by 1.5, then design the structure to fail under factored loads (with a. Mass of conveyed fluid, calculated on the basis of. This calculator provides the calculation of pipe support spacing for a given set of input parameters. A piping system is an irregular 3d structure. Operational loads, accidental loads, environmental loads). The types of pipe supports are very important, because in conjunction with their location as well as the piping geometric configuration and. When calculated, all loads should be taken into consideration (e.g. Each pipe support has its own load carrying capacities depending upon its function. One must check the load limits of that particular support. The loads to be sustained by piping supports are calculated by taking into account all following components. Pipe support design involves the calculation of reaction forces, bending moments, and bending.

From whatispiping.com

Piping Support Types, Purpose, Design, Codes, Optimization Rules How To Calculate Pipe Support Loads Each pipe support has its own load carrying capacities depending upon its function. The loads to be sustained by piping supports are calculated by taking into account all following components. With lsd, we factor dead loads by 1.25 and live loads by 1.5, then design the structure to fail under factored loads (with a. A piping system is an irregular. How To Calculate Pipe Support Loads.

From www.sexiezpix.com

6x6 Wood Beam Load Capacity Chart SexiezPix Porn How To Calculate Pipe Support Loads This calculator provides the calculation of pipe support spacing for a given set of input parameters. With lsd, we factor dead loads by 1.25 and live loads by 1.5, then design the structure to fail under factored loads (with a. Mass of conveyed fluid, calculated on the basis of. The loads to be sustained by piping supports are calculated by. How To Calculate Pipe Support Loads.

From www.assignmentaccess.com

Solved Q.3) A simply supported beam supports the applied How To Calculate Pipe Support Loads This calculator provides the calculation of pipe support spacing for a given set of input parameters. One must check the load limits of that particular support. With lsd, we factor dead loads by 1.25 and live loads by 1.5, then design the structure to fail under factored loads (with a. Operational loads, accidental loads, environmental loads). When calculated, all loads. How To Calculate Pipe Support Loads.

From the3dtelevisionfreeshipping.blogspot.com

pipe support design calculation xls the3dtelevisionfreeshipping How To Calculate Pipe Support Loads The types of pipe supports are very important, because in conjunction with their location as well as the piping geometric configuration and. Each pipe support has its own load carrying capacities depending upon its function. A piping system is an irregular 3d structure. When calculated, all loads should be taken into consideration (e.g. Operational loads, accidental loads, environmental loads). One. How To Calculate Pipe Support Loads.

From www.cannondigi.com

How Do You Calculate Point Load On A Beam The Best Picture Of Beam How To Calculate Pipe Support Loads A piping system is an irregular 3d structure. Mass of conveyed fluid, calculated on the basis of. Each pipe support has its own load carrying capacities depending upon its function. The loads to be sustained by piping supports are calculated by taking into account all following components. One must check the load limits of that particular support. The types of. How To Calculate Pipe Support Loads.

From www.youtube.com

Calculation of Approximate Loads On Column Load distribution YouTube How To Calculate Pipe Support Loads One must check the load limits of that particular support. A piping system is an irregular 3d structure. This calculator provides the calculation of pipe support spacing for a given set of input parameters. With lsd, we factor dead loads by 1.25 and live loads by 1.5, then design the structure to fail under factored loads (with a. The loads. How To Calculate Pipe Support Loads.

From www.pipingguide.net

Determination of Loads And Movements in Piping Supports PIPING GUIDE How To Calculate Pipe Support Loads Operational loads, accidental loads, environmental loads). One must check the load limits of that particular support. The types of pipe supports are very important, because in conjunction with their location as well as the piping geometric configuration and. The loads to be sustained by piping supports are calculated by taking into account all following components. Pipe support design involves the. How To Calculate Pipe Support Loads.

From blog.dandkmotorsports.com

Online Structural Steel Weight Calculator Blog Dandk How To Calculate Pipe Support Loads The loads to be sustained by piping supports are calculated by taking into account all following components. Mass of conveyed fluid, calculated on the basis of. Pipe support design involves the calculation of reaction forces, bending moments, and bending. When calculated, all loads should be taken into consideration (e.g. Operational loads, accidental loads, environmental loads). The types of pipe supports. How To Calculate Pipe Support Loads.

From www.chegg.com

The Pipe Assembly Supports The Vertical Loads Shown How To Calculate Pipe Support Loads The loads to be sustained by piping supports are calculated by taking into account all following components. When calculated, all loads should be taken into consideration (e.g. The types of pipe supports are very important, because in conjunction with their location as well as the piping geometric configuration and. With lsd, we factor dead loads by 1.25 and live loads. How To Calculate Pipe Support Loads.

From www.artofit.org

Load calculator on column and beam column design calculator beam load How To Calculate Pipe Support Loads Each pipe support has its own load carrying capacities depending upon its function. Operational loads, accidental loads, environmental loads). Mass of conveyed fluid, calculated on the basis of. This calculator provides the calculation of pipe support spacing for a given set of input parameters. One must check the load limits of that particular support. The loads to be sustained by. How To Calculate Pipe Support Loads.

From www.paulin.com

Modern Piping Allowable Nozzle Loads & WRC Calculation Methods How To Calculate Pipe Support Loads One must check the load limits of that particular support. The loads to be sustained by piping supports are calculated by taking into account all following components. Pipe support design involves the calculation of reaction forces, bending moments, and bending. This calculator provides the calculation of pipe support spacing for a given set of input parameters. Operational loads, accidental loads,. How To Calculate Pipe Support Loads.

From www.chegg.com

Solved 2. The pipe assembly supports the vertical loads How To Calculate Pipe Support Loads One must check the load limits of that particular support. When calculated, all loads should be taken into consideration (e.g. Pipe support design involves the calculation of reaction forces, bending moments, and bending. This calculator provides the calculation of pipe support spacing for a given set of input parameters. With lsd, we factor dead loads by 1.25 and live loads. How To Calculate Pipe Support Loads.

From www.eng-tips.com

Stacked pipes. Load to upright supports. Structural engineering How To Calculate Pipe Support Loads Pipe support design involves the calculation of reaction forces, bending moments, and bending. One must check the load limits of that particular support. Operational loads, accidental loads, environmental loads). This calculator provides the calculation of pipe support spacing for a given set of input parameters. Each pipe support has its own load carrying capacities depending upon its function. The loads. How To Calculate Pipe Support Loads.

From www.pipingguide.net

Determination of Loads And Movements in Piping Supports PIPING GUIDE How To Calculate Pipe Support Loads A piping system is an irregular 3d structure. When calculated, all loads should be taken into consideration (e.g. One must check the load limits of that particular support. The loads to be sustained by piping supports are calculated by taking into account all following components. With lsd, we factor dead loads by 1.25 and live loads by 1.5, then design. How To Calculate Pipe Support Loads.

From www.researchgate.net

7. Pipe Support Loads Download Table How To Calculate Pipe Support Loads One must check the load limits of that particular support. This calculator provides the calculation of pipe support spacing for a given set of input parameters. Each pipe support has its own load carrying capacities depending upon its function. The types of pipe supports are very important, because in conjunction with their location as well as the piping geometric configuration. How To Calculate Pipe Support Loads.

From www.youtube.com

Types of Pipe Support Used in Piping Seven Main Types YouTube How To Calculate Pipe Support Loads This calculator provides the calculation of pipe support spacing for a given set of input parameters. When calculated, all loads should be taken into consideration (e.g. A piping system is an irregular 3d structure. The loads to be sustained by piping supports are calculated by taking into account all following components. Mass of conveyed fluid, calculated on the basis of.. How To Calculate Pipe Support Loads.

From einvoice.fpt.com.vn

PIPING GUIDE Determination Of Loads And Movements In, 59 OFF How To Calculate Pipe Support Loads This calculator provides the calculation of pipe support spacing for a given set of input parameters. A piping system is an irregular 3d structure. When calculated, all loads should be taken into consideration (e.g. Operational loads, accidental loads, environmental loads). Pipe support design involves the calculation of reaction forces, bending moments, and bending. With lsd, we factor dead loads by. How To Calculate Pipe Support Loads.

From www.vrogue.co

Pipe Support Span Pipe Support Spacing Charttable Pdf vrogue.co How To Calculate Pipe Support Loads The types of pipe supports are very important, because in conjunction with their location as well as the piping geometric configuration and. With lsd, we factor dead loads by 1.25 and live loads by 1.5, then design the structure to fail under factored loads (with a. This calculator provides the calculation of pipe support spacing for a given set of. How To Calculate Pipe Support Loads.